- Home

- News

- How to Create an Optimal Environment for Automation

Phased Automation: Designing the Optimal Environment - Even in Your Current Space

Automation is rapidly transforming manufacturing and distribution environments. But for many facilities, implementing it all at once isn’t realistic — or even wise.

Up-front costs, infrastructure and operational disruption are major barriers to going all in with full-scale loading dock automation or interior automated equipment.

A phased approach is as pragmatic as it is necessary, though. Building out facility automation in structured, strategic stages will minimize risk and maximize long-term value.

Whether you’re retrofitting what you have or designing a new building, these recommended steps will help achieve successful automation implementation.

Know your current-state workflows

We all strive for zero safety events and zero inefficiencies—but achieving such goals doesn’t mean every facility needs to be a fully automated “dark” warehouse.

Start by clearly understanding your facility’s sequence of operations. This empowers you to identify which manual areas are opportunities with the greatest ROI to automate.

Review the top five areas for automation in facilities and determine which phase of automation looks like your current process. What are your goals for the future? Which KPI’s can you measure to track progress toward successful outcomes?

-

Phase 0: Entirely manual. Humans initiate and complete all tasks from manufacturing through yard management.

-

Phase 1: Smart, connected equipment introduced. Dock sensors, light communication systems or restraint status monitors collect data but may not integrate across a full system.

-

Phase 2: Centralized software platform in place. This connects and monitors multiple systems to create visibility into metrics, giving key personnel a greater understanding of performance.

-

Phase 3: Automation replaces manual workflows. Critical functions incorporate partially or fully automated systems that could include robots, vehicles, loaders, pickers and more.

-

Phase X: Pieces in place for ongoing success. Forward-looking automation design considers infrastructure that integrates with emerging technologies and grows with your business.

Understanding where your facility stands right now allows you to plan incremental improvements based on both immediate gaps and long-term goals.

Find opportunities and inefficiencies

Always return to your goals to drive where automation should start—safety, productivity, uptime, etc. — then identify pain points and redundancies in your dock and warehouse operations. Successful automation projects typically include steps with these process categories in mind.

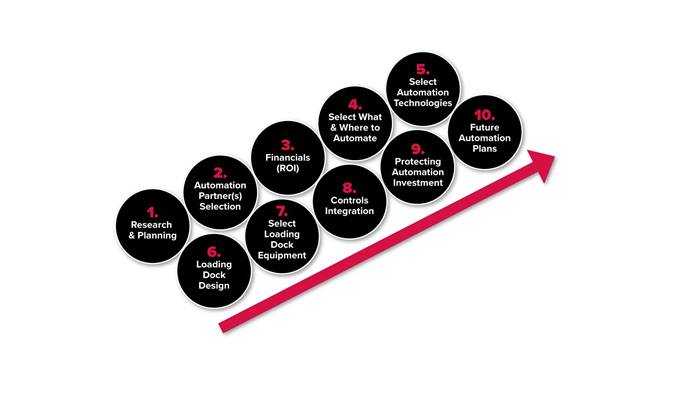

No matter which phase you’re in, begin with the Research & Planning step. This is when you’ll uncover what needs to improve and where automation can help. Ask questions that relate to such concerns as:

Consult data sources like incident logs, warehouse management system reports and connected equipment for insights. These metrics guide decisions for how automation will have the greatest effect on long-term success.

Consider needs for new vs. existing facilities

Starting with a blank slate is often easier than retrofitting existing infrastructures for automation.

For operational facilities, conversions require careful prioritization. Start relatively small with scalable upgrades that easily integrate into current processes.

- Warehouse Management System (WMS) integration: Improves task sequencing and reduces dependency on manual coordination.

- Barcode scanners or RFID tracking: Improves visibility and tracking with minimal infrastructure change.

These systems give you a foundation to eventually layer in more complex automation without disrupting workflows.

When ready to go further, more advanced automation systems can be deployed.

- Autonomous Guided Vehicles and Autonomous Mobile Robots (AGVs/AMRs): Manage repeatable material handling movement between dock and storage.

- Automated Truck Loading System (ATLS): Load and unload trailers in high-volume operations with fewer people needed to manage the dock.

- Automated Storage and Retrieval Systems (ASRS): Robotic picking and sorting in the warehouse has become more accurate and sophisticated on a massive scale.

Even with greenfield or major renovation projects, many teams focus on automation efforts in some areas more than others. Or they design automation for a specific task without considering the entire facility as a connected, holistic process.

Loading docks are often an afterthought if they’re automated at all. That’s a missed opportunity.

Planning for loading dock automation at the design stage prevents costly rework and ensures seamless end-to-end operations.

At minimum, new facilities must consider:

- Dock design best practices: Determine your proper dock height, door centerlines and angle of drive approach incline/decline.

- Equipment selection: Question whether existing equipment has the right capacity for AGV or AMR implementation.

- Controls integration: Ensure your equipment, sensors and future automation technologies can communicate seamlessly.

No matter your circumstances, automation at the dock doesn’t start or end with robots. These are a few of the tools that reduce manual steps or eliminate decision-making at high-risk moments:

If you’re not sure how an automation investment will pay off, start with a pilot program. At an existing operation, this can happen at a single facility or dock position instead of all. And testing different solutions at different facilities or docks gives you more data to make the right decision without pushing all your chips onto the table.

Start laying the foundation

A strong start enables faster deployment later. Mapping processes then kicking off your project with strategic Research & Planning helps you win in the near-term and at scale.

Automation isn’t an all-or-nothing undertaking. A prudent, structured approach allows manufacturing and distribution facilities to adopt new technologies at a manageable pace that’s guided by their unique data, budget and strategic goals.

Rite here for you

Rite-Hite has been a trusted automation partner for more than 15 years, helping successfully complete more than 1,200 automated loading docks. Today, 1 in 5 of our customers are actively exploring or implementing automation strategies — we’re there to help them get started with thoughtful, phased plans.

If your team is considering the next steps for automation, have a conversation with Rite-Hite. We’ll help lay the foundation for successful implementation.

Learn more: Register for on-demand automation webinar series

Contact a representative today to get started