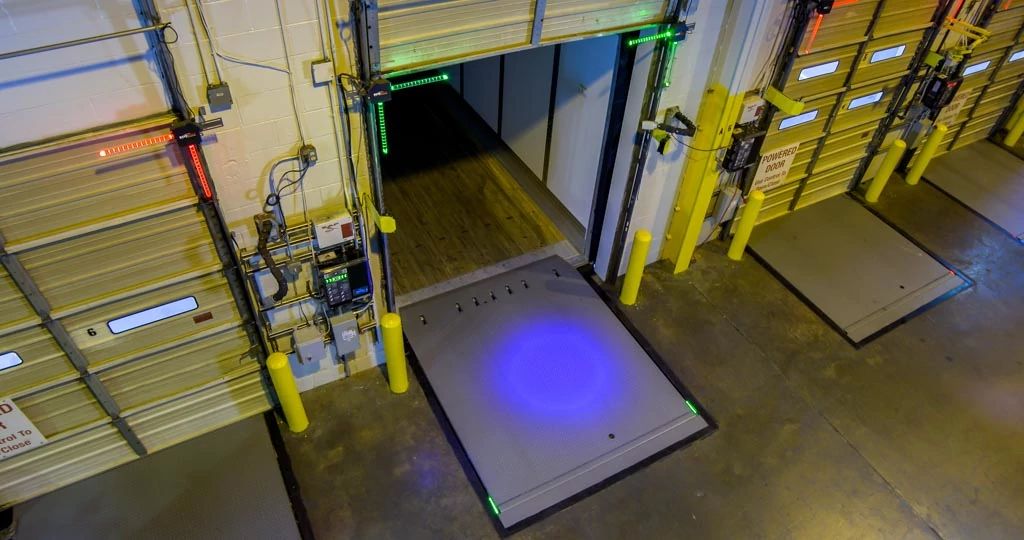

VBR-600 Under Leveler Restraint

Benefits

Designed & Installed for Productivity

Safety at the Loading Dock

Communication and Control

Connected Capabilities

Industry Leading Warranty

- Recessed Design – VBR-600 provides a clean dock face when in the stored position as the restraint is housed under the leveler pit. Ideal for easy clean-up and snow removal on the drive approach, the recessed design also allows access without interference for specialty and lift-gate trailers.

- Leveler Integration – Single power unit allows for combined operation of restraint and hydraulic leveler. Biodegradable Fluid option is environmentally friendly and outperforms traditional industrial-grade fluid.

- Exclusive Barrier Design – 4.25” high barrier with reverse taper design provides the highest and widest coverage on RIGs.

- Positive Engagement Notification – Truck presence bar is depressed upon positive engagement with RIG signaling safe engagement to inside dock attendants. Exclusive mag res switch will not come out of adjustment, helping ensure proper engagement communication.

- Integrity of Installation – Completed dock survey required for each dock position to help ensure safe and proper application of all Dok-Loks. Critical to the safety of material handlers and equipment utilizing the equipment, the surveys are reviewed by expert Applications team if outside of standard dock configuration.

- Pull-Out Force Benchmarks – Rite-Hite was the first loading dock equipment manufacturer to establish pull-out force benchmarks based on years of research and development. Followed today by many other manufacturers, VBR-600 is installed with mounting force in excess of 100,000 lbs. and 32,000 lbs. of pull-out force, doubling what tractors can achieve when in first gear.

- Withstand Harsh Loading Dock Environment – Zinc-plated for all weather durability with front seal brush helping to prevent debris from entering and accumulating in restraint pit.

- Automatic Re-fire technology – Available on automatic ground stored and under leveler models to combat if vertical barrier loses contact with RIG.

- Communication and Control – Dok-Lok® Style Light Communication communicates via interior lights when trailer is properly engaged, thus safe for material handlers to enter.

- Help Prevent Trailer Separation Accidents – VBR-600 helps to prevent early departure and trailer creep during live or dropped loading. For dropped trailers, a trailer stand can assist in helping prevent landing gear collapse and trailer upending.

- Certified to meet and exceed ANSI MH30.3 performance testing standards.

Rite-Hite Communication and Control allows facilities to:

- Integrate additional/future equipment and interlocked sequence of operations with Dok-Lok® Style Light Communication System.

- Incorporate line of sight light communication system status with Corner-Vu™ and Leveler-Vu™.

- Extend Blue Light Policy to help prevent 80,000 annual forklift-pedestrian accidents by extending reaction time with Pedestrian-Vu™.

- Help prevent 2nd leading cause of backover fatalities in the United States with Approach-Vu™, which utilizes a light and horn system to present a clear visual and audible warning to pedestrians in the drive approach when a backing vehicle is detected.

- Verify Dok-Lok engagement and trailer stand presence via outside camera and inside monitor with Lok-Vu™, reducing the amount of processes on the dangerous drive approach.

- Integrate multiple loading dock control components at each dock position for a total dock safety system with Dok-Commander® Combined Controls.

All components are available as standalone or incorporated with Dok-Lok Style Light Communication System. The Dok-Lok Style Light Communication System offers more flexibility, facilitating the greatest long-term yield per dock position. The system allows facilities to address their most urgent safety needs first but reserving the opportunity to integrate vehicle restraints and other safety solutions at a fraction of the cost compared to standalone equipment purchases.

Want more visibility into dock performance for safety and productivity?

Dok-Lok Vehicle Restraints are Rite-Hite ONE-enabled.* Connecting to this single Digital Platform provides real-time visibility and data to empower maintenance decisions, reduce inefficiencies and help mitigate safety events.

- Safety. Real-time alerts delivered to any device to identify and stop unsafe behavior, such as:

- Dok-Lok overrides and/or fault modes.

- Employee entering an unrestrained trailer.

- Dock door open but safety barrier not deployed.

- Productivity. Analytics gathered during each step of the loading process to identify bottlenecks and optimize operations, such as:

- Total duration of loading, to help avoid detention costs.

- Equipment utilization to determine under- or -over-usage.

- Trailer at dock but restraint not yet engaged.

- Uptime. Visibility into connected equipment status and service history, such as:

- Designate equipment state (out of service or immediate repair service required).

- Equipment performance trending down (cycle counts, use, service history).

- Document and log maintenance and services events.

* Rite-Hite ONE subscription required.

- 12-Month Limited Money-Back Guarantee of Customer Satisfaction

- Standard Warranty includes 1 year parts / 1 year labor

- Rite-Hite® Extended Warranty includes 2 year parts / 1 year labor and connected capabilities

Gallery

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.