RHV-4100 Vertical Storing Hydraulic

View

Someone from our team will be in touch with you shortly.

Automation has become a cornerstone for sustainable growth in any industry where material handling is critical to operations. Adoption of AGVs and other automation technology is accelerating.

That’s readily apparent in factories and warehouses. Where automation often gets overlooked is at the loading dock. And the need to mitigate safety events while upping productivity is no less urgent there than anywhere else.

However, urgency shouldn’t get in the way of smart automation solutions that help companies achieve that sustainable growth. A clear vision and careful planning take time. Types of technology, dock design, equipment selection and controls application are keys to success.

Experience matters for safety and productivity. But in a tight market for talent, labor shortages, nearshoring and skills gaps mean experience is harder to come by.

Travelers reported in 2024 that 30% of injuries in manufacturing occurred during a worker’s first year on the job. That report states that those manufacturing employees lost an average of 67 workdays due to injury.

Regardless of the factors, bottom line is that facility, operations and safety managers must fill vital roles — even as customers demand more, faster. Achieving throughput goals gets more difficult.

Short version? Your loading dock — part of the material transfer zone — is a critical area for finding new opportunities for improved safety and productivity. Loading dock automation solutions can help.

Your material transfer zone (MTZ) is more than just your dock door and loading dock leveler. It extends 100′ outside on the drive approach and 100′ inside to your facility’s staging area.

A truly automated dock requires automation that covers the entire MTZ and flows seamlessly from inside the facility out into the yard.

With labor at a premium, overworked employees may resort to unsafe shortcuts for established procedures. Automation specific to the material transfer zone benefits facilities in several ways:

Rite-Hite has successfully completed more than 1,200 loading dock positions designed for automation, making us the partner of choice for more than 15 years.

Ultimately, we help drive our partners toward zero safety events, zero security incidents, zero unplanned downtime and zero inefficiencies. The first step is successful completion of your loading dock design project.

Our definition of “successful completion” is simple:

But the process to achieve this on time and on budget can be more complex.

To ensure success, Rite-Hite automation experts serve as consultants for companies, beginning at their earliest planning stages.

At the outset, we help identify your current processes and pain points to uncover what, where and why our partners would benefit from automation solutions in the material transfer zone. Throughout this process, our focus is on making the most out of your automation investment for long-term success — while maximizing efficiency and productivity from the start.

Rite-Hite’s global headquarters was built with you in mind. During your in-person (or virtual) visit our team of automation professionals will take you through an in-depth conversation of your challenges and tailor personalized education, on possible solutions, with the end goal of helping discover what success looks like for your unique project.

Our one-of-a-kind Customer Experience Center (CEC) features a live loading dock with Rite-Hite equipment, sensors and controls ready to operate — giving you hands-on experience in an environment with full-sized trailers.

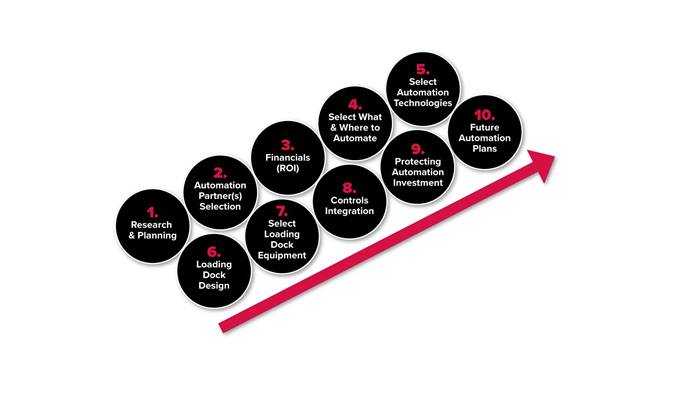

Everyone’s path to loading dock and facility automation is unique. But all are long-term investments. As with any journey, proper preparation gets you where you want to be. If you're not ready for an in-person visit, learn more by registering for our on-demand webinar series on loading dock automation. The series guides you through crucial milestones for how to bring a loading dock automation project to a successful completion. From research and planning through protecting your investment and planning for the future, the educational series brings in knowledge experts from across the industry to tackle the ins and outs of a successful automation project.

Register for on-demand automation webinar series

Your answers to our questions determine the right combination of autonomous solutions with dock design, dock equipment, controls integration from the list below performing together for success.

Contact a representative for more loading dock automation info or to connect about a CEC visit.

Automation helps facilities increase productivity and safety at the loading dock — provided it’s expertly designed and implemented. Take appropriate measures to ensure this happens by bringing partners into the process early. Rite-Hite’s loading dock automation team makes custom recommendations based on your goals, challenges, equipment options, workforce, budget, infrastructure and other factors to help get you where you need to be. Learn more from a loading dock automation expert today.

Contact an Automation Loading Dock Expert for More Information

Fill out the form below and one of our reps will reach out to you.

Someone from our team will be in touch with you shortly.