- Home

- News

- Top 5 Areas to Automate in Your Facility

Top 5 Areas to Automate in Your Facility

Productivity and safety are two main drivers for companies embracing automation. Many will think of robots when considering automation — especially for repetitive or hazardous tasks.

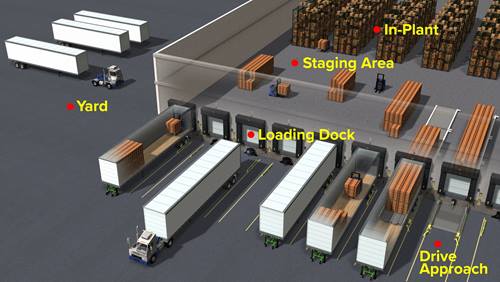

Automation is more than robotics in manufacturing processes, though. You have opportunities to lower total costs of goods sold, improve safety and increase efficiency across your entire facility, even out into the yard. As part of project planning, it’s important to understand the pros and cons of automation in these top five key areas:

- In-plant

- Staging

- Loading dock

- Drive approach

- Yard

In recent years, each has become prime for all types of automation. With careful planning and smart investing, each type holds benefits for specific applications — a harmonious, seamless solution is only effective with an up-front, wholistic vision. And each can help improve productivity and safety.

1. In-plant automation

The evolution of warehouse automation technology has accelerated. Automated Storage and Retrieval Systems (ASRSs) aren’t new — but their sophistication in picking and sorting items on a massive scale has transformed warehouses and distribution centers in recent years.

Automation has evolved with ecommerce to nimbly handle small, individual products. ASRSs now integrate with enterprise resource planning tools and warehouse management systems (WMS) for real-time inventory tracking. Collaborative robots (cobots) assist employees with tasks. Autonomous mobile robots (AMRs) move materials through environments independently. And mobile ASRS solutions have emerged to make spaces more flexible. Pallet jacks (single-unit load AGVs) or pulling carts (tow tractor AGVs) move smaller loads.

Advantages

- Speed, safety, accuracy

- Vertical/horizontal space optimization

- Real-time inventory tracking

- Reduced total operating costs

Disadvantages

- High initial costs for equipment and infrastructure

- Complex installation with customized, site-specific specs

- Difficulty adjusting to major changes in inventory

Applications

- eCommerce and retail warehouses

- Automotive distribution centers

- Food and beverage in cold storage

- Pharmaceuticals in secure facilities

2. Staging area automation

This critical zone serves several purposes, including shipping, receiving, sorting, palletizing, labeling, wrapping, and staging goods so they can be easily loaded into a trailer or distributed within the facility once unloaded. With everything required of this floor space, it can easily become a major bottleneck. No single piece of equipment will automate all tasks — integrate the appropriate equipment to build an efficient staging area that connects your warehouse and loading dock.

Different types of conveyors bring different levels of automation. Some conveyors are not connected — AMRs and autonomous guided vehicles (AGVs) might feed them, then gravity alone delivers goods to the trailer area. Others include sensors that detect goods and activate conveyor movement to transport goods. Fully automated conveyors load and unload goods at the truck trailer’s edge and adjust the flow of goods to avoid jams.

Advantages

- Ensures a steady, manageable flow of goods

- Reduces damage to packages

- Heightens accuracy and flexibility

- Enhances efficiency in operations

Disadvantages

- Requires synchronization with multiple parts

- Requires ample space to accommodate

- Requires occasional reconfiguration with specific instructions

Applications

- Warehouses and distribution centers

- Manufacturing facilities

- Food production and packaging plants

- Loading and unloading operations

3. Loading dock automation

Loading docks are a system of equipment working in coordination for loading and unloading trailers. Some can be automated or connected or simply supportive in this process. In the material transfer zone, autonomous guided vehicles (AGVs) often handle moving goods into and out of trailers. AGVs might be autonomous (or hybrid) forklifts of various size and capacity.

An automated trailer loading system (ATLS) operates in one direction unless the trailer itself is modified. The ATLS helps automate the loading process to increases trailer throughput with fewer people to manage the dock, freeing them up for higher value tasks.

Key variables that can negatively affect the movement of materials at the loading dock include trailer position, weather and how the materials are (un)loaded inside the trailer (i.e. palletized or use of dunnage). Technology that uses sensors, including AGVs, typically needs level ground and stable conditions free of dirt and debris. To create an optimal environment, dock seals and shelters can help keep outdoor elements from getting inside, while levelers and vehicle restraints give AGVs a smoother path.

Advantages

- Increased worker safety, fewer injuries

- Operational speed and consistency

- Mitigating human error with precision

- Reduced labor costs

Disadvantages

- High initial cost for equipment and infrastructure

- Requires ample floor space (for ATLS)

- Potential disruption due to environmental factors (for AGVs)

- Most units still require at least one worker per several dock positions to initiate the process to start

Applications

- Warehouses and distribution centers

- Manufacturing facilities

- Automotive and agriculture industry facilities

- Facilities that ship palletized, high-volume, low-SKU products

4. Drive approach automation

Even though it’s outside, this is a potentially dangerous area of your facility. Beyond back-over hazards, momentary lapses in attention or poorly maintained equipment can cause landing gear collapse, pop-ups and upending.

These potential accidents are one of the many reasons facilities look to equipment that keeps their employees inside the facility as part of a boots-off-the-ground policy. Powered trailer lifts raise the trailer to match dock height and automatic wheel-based restraints can be integrated into a sequence of operation with the trailer lift to keep workers off the drive approach. Sensors recognize hazards to improve communication on the approach with visual and audible alarms. Because monitoring the exterior drive approach is crucial to being productive inside.

Advantages

- Increased worker safety, fewer injuries

- Less unplanned downtime due to accidents

- Workforce able to focus on higher value tasks

- Fewer open job positions to fill

Disadvantages

- Some up-front costs for replacing equipment

- Learning curve to establish new processes

Applications

- Logistics warehouses and distribution hubs

- Industrial sites

- Facilities with high-traffic material transfer zones

- Docks with angled, short or tight drive approaches

5. Yard automation

Your yard is essential to keeping an efficient end-to-end operation — facility automation helps arriving and departing trucks adhere to strict schedules. At the same time, it gives drivers a rest and keeps your team doing more valuable, more skilled work.

Truck drivers are in control with hitting tight windows for arrival. From there, automation can handle check-in at the gate and trailer inspections. Autonomous yard spotters (AYSs) remove the human element moving trailers with first-time precision throughout your yard to facilitate faster turnaround times to keep traffic moving and throughput optimized.

Advantages

- More efficient operations

- Less idle time for drivers waiting

- First-time precision

- Reduced risk for product, equipment and infrastructure damage

Disadvantages

- High initial costs to implement appropriate equipment and infrastructure

- Learning curve to establish new processes

Applications

- Logistics warehouses and distribution hubs

- Industrial sites

- Facilities with high-traffic yards and/or limited yard space

Looking ahead

Knowing your options for automations in all five key areas is essential to reducing overall cost while increasing efficiencies. In-plant, staging, loading dock, drive approach and yard can each significantly impact the others in your end-to-end processes.

Rite-Hite has designed more than 1,200 loading dock positions for automation, making us a partner of choice in this space for over 15 years. Our team knows what’s possible today and what will make your evolution for future automation easier. We collaborate and consult with architects, contractors, automation suppliers and manufacturers, and integrators to help ensure all partners are working toward your project’s successful completion.

Nobody wants to play catch-up. Especially when the stakes are higher and your investment to transform operations gets steeper. Learn what’s possible and what considerations are crucial to success with a free automation-focused assessment of your loading dock and other areas.

Learn more: Register for on-demand automation webinar series Contact an automation loading dock expert