- Home

- News

- Which Loading Dock Leveler Is Right For You

Which Loading Dock Leveler Is Right For You?

With several loading dock leveler designs available on the market, there’s a decision to be made regarding which leveler is best for your application. Aspects such as industry, trailer types, number of shifts, and gross truck load weight are important considerations for facilities to make during research. Continue reading to learn more about the different loading dock leveler options by industry and applications.

Types of Loading Dock Levelers

Edge of Dock Levelers

A type of loading dock leveler that is mounted to the face of the building (no poured concrete pit) and has two operational choices. The first, an edge of dock leveler can be operated mechanically by an operational handle that is used to manually lift the leveler and lip up from the stored position and place it into the trailer bed. Second, it can be operated hydraulically by simple two button (up and down) controls. Both are good options for facilities that have minimal variation in bed heights of the vehicles they service.

Mechanical Dock Levelers

A type of pit style loading dock leveler that is manually operated. Different from the mechanical edge of dock leveler, mechanical dock levelers are installed into a pit at the loading dock door and require an operator to pull a chain to activate the leveler and then place it in the back of the trailer bed. These are both cost-effective options for facilities who experience basic shipping / receiving needs with lighter weight materials being transferred.

Air Powered Dock Levelers

Similar to the hydraulic edge of dock leveler, Air Powered dock levelers utilize a button located on a control panel to raise and lower the leveler. The main difference is that they are powered using pressured air versus a hydraulic cylinder. Their easy wash-down air tower and frame allows for quick removal of dirt and debris between loads; ideal for facilities with strict sanitation regulations.

Hydraulic Dock Levelers

A type of loading dock leveler that, rather than a dock attendant needing to manually pull on a chain or operate a handle, the hydraulic dock leveler deck and lip are able to raise and lower at the touch of a button and can handle higher gross weight and frequency loads. Perfect for face-paced facilities that may transfer more demanding freight.

Dock Levelers by Application

Industry needs can make a crucial difference in the type of levelers your docks should have. It all depends on the goods that are being picked up and/or received. We’ve put together a guide to help you in your research.

Strict Sanitation Regulations

Facilities, such as the food and beverage industry, move a significant amount of product with extremely strict regulations. To help increase efficiency, a dock leveler with push-button operation is recommended. Selecting an air powered dock leveler provides this solution and has an easy wash-down air tower and frame - a perfect solution for strict sanitation requirements. For a hydraulic option, the RHH-4000 is another push-button control-operated choice and is available with biodegradable fluid.

Browse our Hydraulic Dock Leveler Line-Up Browse our Air Powered Dock Leveler Line-Up

Environment & Temperature Controlled

Facilities that require additional amenities out of a dock leveler, due to the role that temperature plays in its products, need more control of the environment in regards to either air infiltration and cross contamination. Hydraulic vertical dock levelers are designed to help provide superior environmental and security control while maintaining smooth operations. Vertical Storing dock leveler allows facilities that utilize a drive-thru approach to open trailer doors inside the building, making it an ideal choice for when it comes to temperature control.

Learn More About Vertical Storing Dock Leveler

Full-Width & Full-Height Loading

To get the most out of a trailer's capacity, many facilities will use the method of cube-loading to maximize the amount of space. This process requires accuracy and speed to load the trailer dimensions, while still keeping assembly lines going. To have the ability to move quickly and efficiently, warehouses will often have custom designed loading docks to ensure precision loading and maximum utilization of trailer space. Rite-Hite’s RHJ-5000 Jumbo hydraulic leveler allows material handlers the ability to contact the full-width of the trailer for unparalleled end-load access to help increase productivity, safety, and performance.

Learn More About RHJ-5000 Jumbo Dock Levelers

Heavy Weight & High Frequency Loads

Weight-bearing industries such as the Paper, Pulp, and Packaging industry require a dock leveler engineered to handle more weight. As demands continue to rise, so do the amount of loads that are coming and going, making the Rite-Hite RHH-5000 High Capacity hydraulic leveler a viable option for this industry. Facilities that also move a high volume of product or perform cube loading of trailers could also benefit from the RHJ-5000 Jumbo Dock.

Learn More About RHH-5000 High Capacity Hydraulic Levelers

Consider Vehicle Bed Height

In addition to industry and applications, the maximum and minimum height of the vehicles that frequent your loading dock is another consideration when selecting a dock leveler. Depending on the vehicle height, this determines the leveler’s working (or operating) range and may affect which loading dock leveler is best suited for the dock position. Last, but not least, the gross weight being transferred across a dock leveler will greatly impact the final product selection.

**Total Gross Weight is defined as the maximum amount of weight that will be

traveling over a dock leveler; material transfer device plus the weight of the materials.

Traditional standard over the read (SOTR) semi-trailers can benefit from conventional mechanical and hydraulic levelers while smaller box trucks, delivery vehicles, especially with liftgates, may require specialized leveler or lift functionality and additional attention to what vehicle restraint is used at the dock. Aside from the vehicle height, goods, and vehicle restraints, it’s important to think about the loading process. For example, is a simple dolly being utilized or will a forklift be driving onto and off of the trailer?

Consider Loading Dock Performance Standards

Perhaps one of the most important considerations when choosing a dock leveler is gross load frequency, or more commonly confused with capacity (static weight only). In order for safe operation, not only should the dock leveler be able to handle the gross load weight, but also factor in how many loads will be crossing it on a daily basis. Failing to accommodate factors outside of a simple static capacity poses severe safety risks and can lead to serious injury.

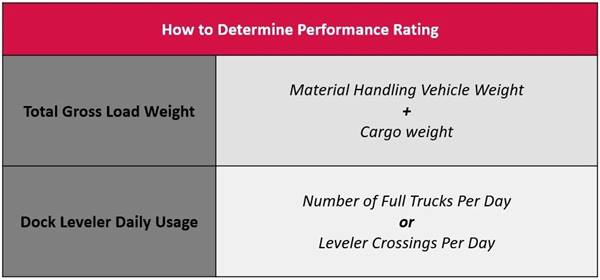

An absolute must for determining the performance rating required for your loading dock leveler is accurately knowing these two factors:

Your loading dock leveler should be rated on how it is used and handle no more than the determined gross load weight needs of your operation. Work with your local Rite-Hite representative to decide which performance rating best suits your facility’s needs based on application and usage. Listen to the Performance Standards Podcast on Performance Ratings for more information on determining gross load frequency.

Contact Rite-Hite Today

If you are a facility manager, architect, general contractor or anyone else who is tasked with selecting a loading dock leveler, these topics will help serve as a base for your research. However, if you are still unsure about which loading dock leveler is right for you, contact one of our reps today. They’ll be happy to help answer any questions you have and direct you to the loading dock best for your needs.

Contact Your Local Rep