- Home

- News

- Convection & Conduction at the Door Opening

Convection & Conduction at the Door Opening

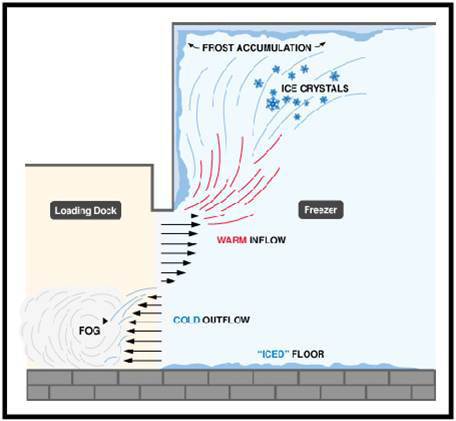

Cold storage facilities have all types of traffic moving between ambient to cooler to freezer temperatures. No matter what the product is that's being stored in these facilities, the objective is to keep the product cold or even frozen. Another goal is to keep the storage space as dry as possible. When there is a lot of air transfer between ambient, cooler and freezer temperatures, humidity can cause ice and snow to build up in the freezer. Reducing heat transfer between rooms is job #1, and can be categorized with two terms: Convection and Conduction.

Convection is the air exchange which transfers thermal energy (heat or warmer temperature) into the cooler area (refrigerated or freezer storage area). This not only raises the temperature of the freezer, requiring more energy to remove the heat, but also brings more humidity to this critical control point. Accumulation of ice and snow can increase when the warm moist air comes into contact with the cold dry air. In order to reduce ice and snow accumulation, a tight door seal and reduced door cycle times are critical.

Conduction is the heat transfer through a substance or, in this case, the door panel. Cold storage doors usually have a certain thickness (R-Value) to reduce the heat transfer through the panel. In other words, thicker door panels transfer heat slower than thin curtains or panels. With conduction being only a fraction of the energy lost compared to convection, R-Value has some diminishing returns. Under most freezer conditions, you need an R-Value of 4 or greater to avoid having to use energy-inefficient heat lamps or heated blowers to keep ice from accumulating on the door panels. These extra defrost systems can cost your company thousands of dollars. However, having a thick paneled door can also cost you energy savings because, in most cases, thicker doors mean slower speeds and when it comes to traffic going through the door opening, the transfer of heat is increased. So, in an effort to reduce the heat transfer that leads to humidity and ice/snow accumulation without spending extra dollars on additional heating products, you have to find a “happy medium.”

Rite-Hite Doors provides that “happy medium” with the high speed FasTrax® FR and bi-parting Barrier® Glider. Both door designs do not require any expensive defrost systems and have the industry-leading opening and closing speeds needed to keep heat transfer, and ice/snow accumulation, to an absolute minimum.

Back to News