- Home

- News

- 5 Ways Curtain Walls Add Value to Your Food Processing Facility

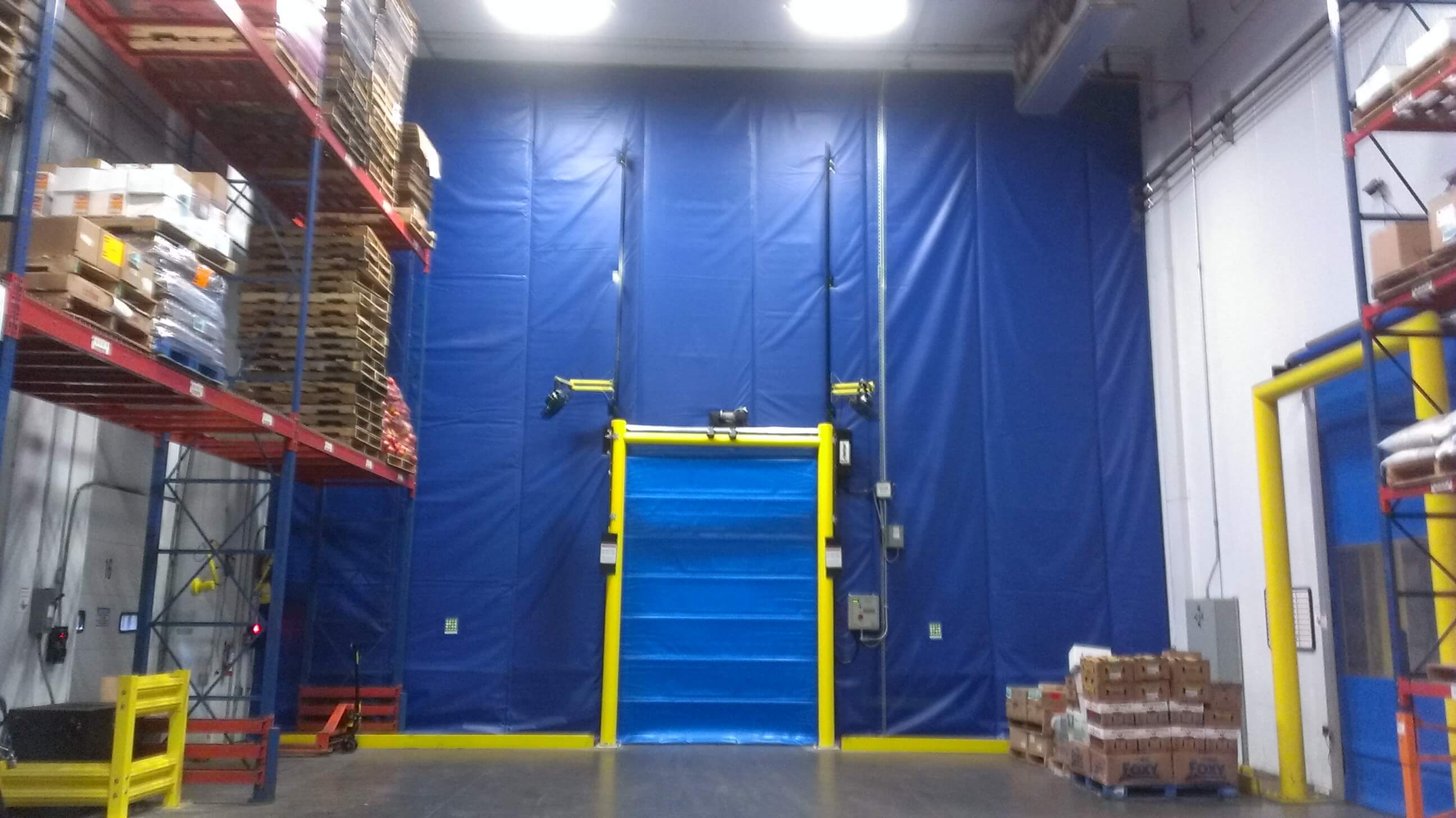

5 Ways Curtain Walls Add Value to Your Food Processing Facility

The name says it all - flexible fabric curtain walls. These versatile structures can be used for just about any purpose. Here are 5 ways for food processing facility managers to use these highly adaptable systems and realize significant value in the process:

1) Create temperature-controlled rooms. Insulated fabric walls can be mounted to existing ceiling structures or built with an affordable framework. As such, they provide an affordable and relatively fast way to create temperature-controlled rooms for separating raw ingredients or end-products and storing them in proper environmental conditions.

2) Subdivide freezer and cooler space. Install insulated curtain walls to isolate and keep products stored at the proper temperature in walk-in coolers and freezers. For example, one section of a freezer can be partitioned off to keep ice cream at -20o F, while other frozen products can be stored separately at higher temperatures. In so doing, the walls contribute to quality assurance goals and extend product life. Additionally, the freezer doesn't have to work overtime to keep only one product at an ultra-low temperature, which results in significant energy savings.

3) Contain odors. Quickly install flexible fabric walls to prevent unwanted odors from one ingredient or finished product from penetrating the other. The practice also adds to employee comfort since the walls keep harsh odors from reaching people working in production and/or storage areas.

4) Gain control over food dust. Effectively seal off processes that involve food dust, whether it's flours, cocoas, cereal ingredients, or the like. Flexible fabric curtain walls limit the potential for food dust to travel, which is beneficial for a host of reasons, including safety, quality assurance, and production machinery maintenance, to name a few.

5) Isolate wash downs. There's no need to halt production in one area due to a wash-down on another production line or process area. Instead, use movable, sliding fabric curtain walls to easily isolate the production line/area for cleaning while other areas remain fully operational.

Back to News