Loading Dock Design Part-1

Improper design and planning of your dock facilities can lead to expensive, time-consuming and serious safety issues. Questions to ask yourself when designing the Material Transfer Zone:

1. What length should my drive approach be?

The American Trucking Association (ATA) in their guide “How Big is a Truck, How Wide Does it Turn” recommends that the drive approach length should be at least twice the length of the longest tractor/trailer combination plus 5’ – 15’ depending on overhead dock door centerlines.

Example: 75’ Tractor/Trailer Length With 12’ Overhead Door Centerlines:

Tractor/Trailer: 75’ X 2 = 150’ + 15’ for Tight Centerline = 165’ Drive Approach Length

110’ – 120’ is NOT long enough for today’s tractors/trailers, in most cases you need at least 150’.

2. Incline, Decline or Level Drive Approach?

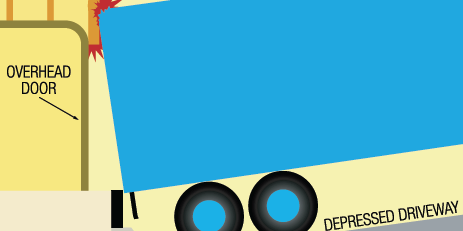

Most new “Big Box” buildings are built with a level or slight incline (1/2%) over the first 50’-75’ for proper drainage. If your site conditions dictate a decline approach, make sure to protect the building!

Add 1” of additional dock bumper projection and/or building wall setback for every percent of drive approach decline.

3. What are the different types of loading docks?

- Flush

- Cantilever

- Open Platform

- Free Standing Dock Ramp

- Saw tooth

- Dock House

- Finger Dock

Part 2 of this series will continue with further questions to ask yourself when designing a dock. Until then, your comments and questions with regards to typical problems and issues are more than welcome.

Back to News