RHV-5000 High Capacity Vertical Storing

Benefits

High Performance Loads

Environmental Control

Smooth Transition Dok System®

Industry Leading Safety

Warranty

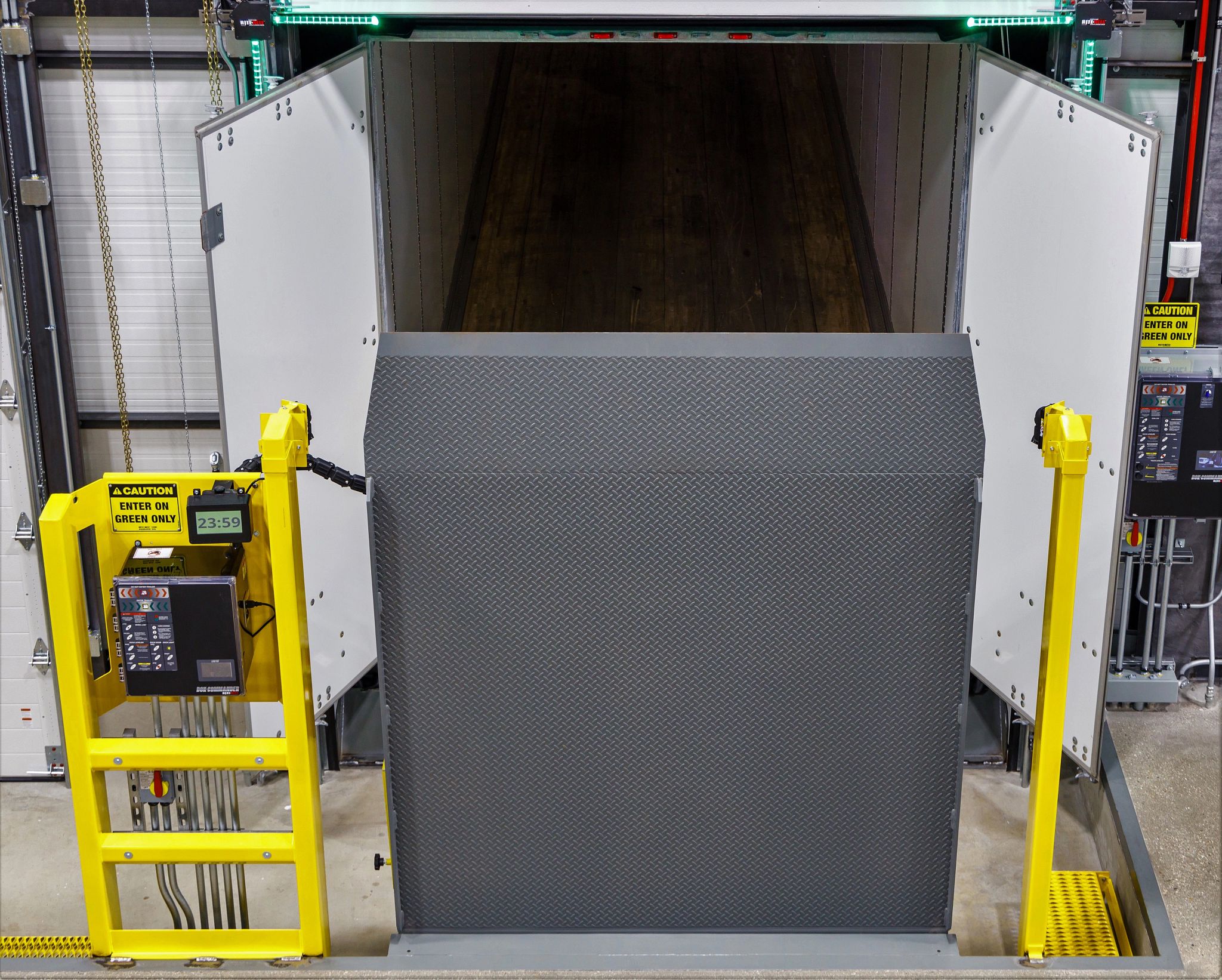

The RHV-5000 Vertical Storing High Capacity Dock Leveler is designed to provide a smooth transition between loading docks and trailers. The leveler's construction and materials are of robust quality, ensuring its durability and ability to withstand the rigors of heavy usage over an extended period, making the RHV-5000 an ideal choice for industries that manufacturer with or produce heavy items. Key features support high performance even with heavier loads include:

- Smooth Transitions: The dock leveler is engineered to facilitate smooth transitions between loading docks and trailers, enhancing operational efficiency.

- Suitable for Heavy Materials: The leveler's rectangular box construction design and fortifying I-beams make it well-suited for industries dealing with substantial and cumbersome loads.

- Durability: Built with strong materials and robust construction, the leveler is built to endure heavy usage while still providing the ability to flex under it's own weight to help prevent Dock Shock when the trailer is not fully parallel with the warehouse floor.

- Three Capacity Options: RHV-5000 is available in three capacity options, catering to a wide range of warehouse environments and requirements.

The RHV-5000 Vertical Storing High Capacity Dock Leveler proves to be a versatile solution for a variety of facilities with diverse needs. It is ideal for industries such as pulp and paper, where not only is the material being transferred substantially heavy, but the forklift requires hefty attachments to transfer them across the dock leveler.

Ideal for facilities that require environmental control, vertical storing dock levelers provide a tight seal between the loading dock and trailers. This seal minimizes air exchange, leading to a variety of benefits including:

- Temperature Regulation: Maintaining consistent indoor temperatures is crucial for industries like food production and storage, pharmaceutical and manufacturing. Vertical dock levelers allow the overhead door to close completely to the warehouse floor to help regulate the temperature inside the facility.

- Debris and Pest Prevention: Drive-thru applications with the aid of weatherseal, shelters, and under-leveler seals help block dust, debris, and pests from entering, ensuring clean and sterile environments.

- Air Quality: Limiting pollutant infiltration for improved indoor air quality and healthier working conditions.

- Employee Comfort: Creating more comfortable workspaces for employees near loading docks.

A standout feature of the RHV-5000 is the Smooth Transition Dok System®. This advanced system is designed to provide a smooth transition between the leveler and the trailer, minimizing the impact of Whole Body Vibration (AKA “Dock Shock”) by up to 16%. Key components of this system include:

- Constant Radius Rear Hinge: Maintains a minimal gap to reduce dock shock when travel across the leveler. This also helps to minimize debris from falling into the leveler pit for reduce cleaning efforts.

- Two-Point Crown Control: The front leveler hinge can often be a common place for repair, as it takes the brunt of the forklift and cargo weight during loading and unloading. Two-point crown control reinforces the hinge and redistributes the weight through the leveler deck and frame, prolonging hinge life.

- Extended Lip Chamfer: The leading edge of a lip can be a source of Whole Body Vibration, that can lead to chronic back pain. By extending the lip chamfer, there is a smoother transitions from leveler lip to trailer bed.

- I-Beam: Rite-Hite's dock leveler beam structure ensures that each I-Beam is no more than 8 inches apart. This design helps strengthen deck, prevents lip pop-up, jarring impacts, hazardous gaps.

- Compatibility with Modern Forklift Design: Further reduces dock shock.

The RHV-5000 high-capacity vertical storing dock leveler is equipped with a range of safety features that enhance its usability and help prevent accidents. These features include:

- Safe-T-Pit™: Disables leveler operation when movement is detected in the pit. The Interlocked Controls will not allow leveler operation to resume until the pit is cleared and the operator is safely at the control panel.

- Maintenance Pin and Vertical Upright Storing: Helps create a safer routine service environment with easy access for pit cleaning and optional full wash-down capability with remote power.

- Dual Tilt-Back Mechanisms: Positions the leveler over center, protecting the hydraulic cylinder from over extension and reduces stress on the rear hinge to help prolong equipment life.

- Rear Hinge: Design has easy access greaseable stainless steel hinge pins.

- Constant-Contact Controls: Allow the operator to extend lip or stop platform and lip at any time during leveler travel – keeping the operator safely at the control panel at all times.

- Access Brace: Comes standard on all continuous pit applications, boosting pedestrian safety.

- Non-Adjustable Velocity Fuse: Helps stop rapid leveler descent with a heavy load on the platform; providing ultimate free-fall protection.

- Vertical Storage Positioning: Enables safer routine maintenance with easy access for pit cleaning or wash-downs.

Rite-Hite warranties are backed by an exclusive network of representatives and industry leading planned maintenance programs, helping to ensure that products perform to their full potential.

- Up to 20-Year Money Back Warranty Based on the Dock Leveler Investment Guide.

- 5-Year Parts and 1-Year Labor.

- 12-Month Limited Money-Back Guarantee of Customer Satisfaction.

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.