RHV-4100 Vertical Storing

Benefits

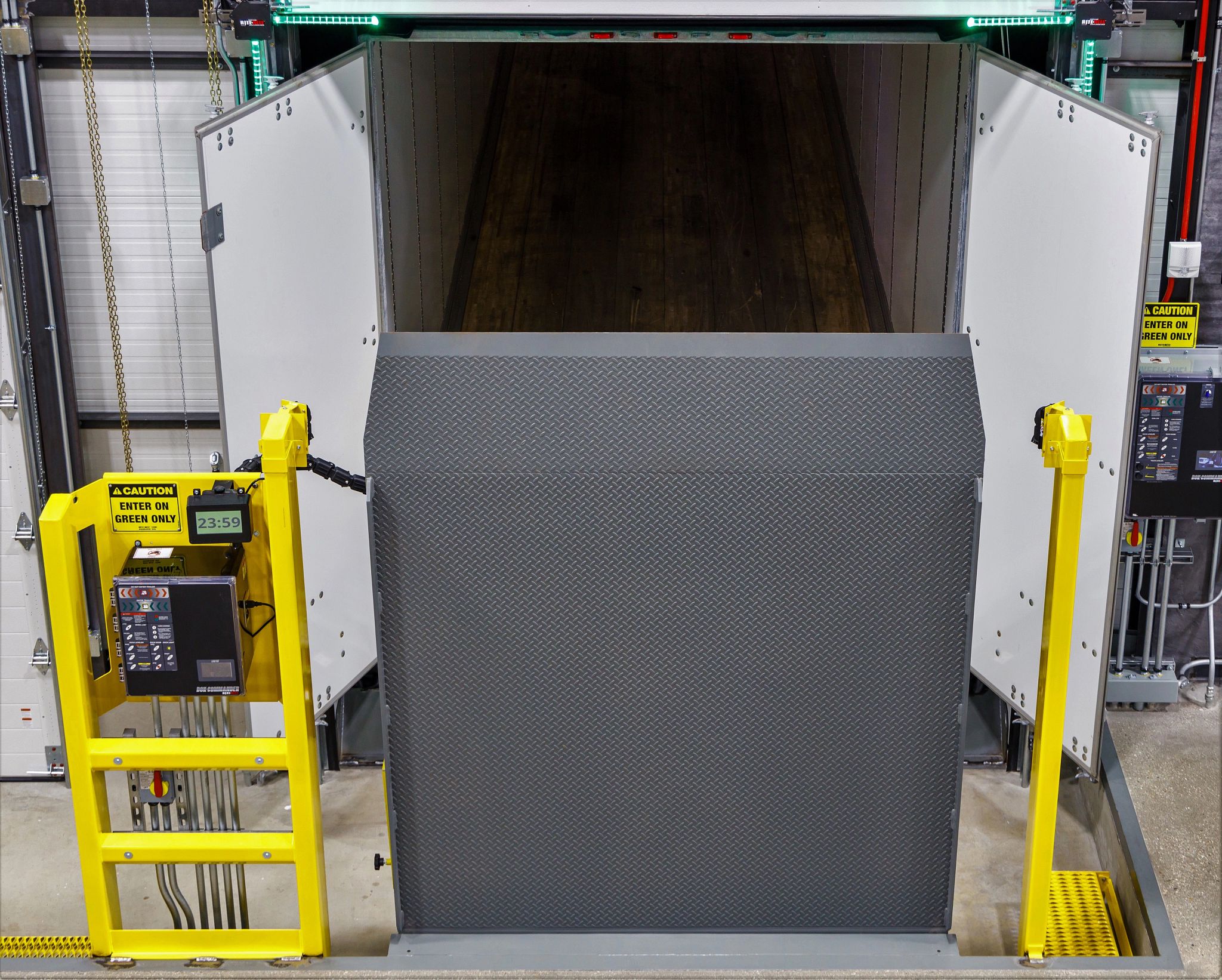

Drive-Thru Approach & Environmental Control

Industry Leading Safety

Productivity

Smooth Transition Dok System®

Warranty

Rite-Hite’s drive-thru design is constructed to help maintain cold chain integrity, environmental control, safety and security; ideal for food or cold storage.

- Vertical Storing leveler allows trailer doors to open inside the loading dock instead of on the drive approach. This helps reduce dust, debris and rodents from entering the facility and eliminates the energy loss from a pit style leveler when stored.

It also means security seals are always removed and placed from inside the facility, improving cold chain integrity and enhancing the security of products and processes.

- Overhead doors close all the way to the pit floor to maximum environmental control. Option to pair with an under-leveler seal and dock shelter, the loading dock will have complete 4-sided contaminant protection; blocking white light.

The importance of safety at the loading dock cannot be understated. From the loading / unloading process to planned maintenance, there are many places to prioritize for safety.

- Safe-T-Pit® utilizes sensors that disable leveler operation when movement is detected in the pit for an additional layer of pedestrian safety. The Interlocked Controls will not allow leveler operation to resume until the pit is cleared and the operator is safely at the control panel.

- Self-Flexing Deck utilizes L-beam stringers to increase deck strength and allow the leveler deck to flex up to 4” under its own weight. This structural design means the leveler maintains constant contact with the trailer bed at all time; even after the weight of the forklift has been removed from the deck.

- Over-Center Tilt-Back Storage of the leveler reduces pressure on the hydraulic system to help prolong equipment life.

- Constant-Contact Controls: Allow the operator to extend lip or stop platform and lip at any time during leveler travel – keeping the operator safely at the control panel at all times.

- Non-Adjustable Velocity Fuse helps stop rapid leveler descent within 3" (76 mm) with a heavy load on the platform; providing ultimate free-fall protection.

- Access Brace: Comes standard on all continuous pit applications, boosting pedestrian safety.

- Vertical Storage Positioning: Enables safer routine maintenance with easy access for pit cleaning or wash-downs.

Help cut down facility costs by increasing productivity through boots off the drive approach, effortless constant-contact controls, and high performance, biodegradable fluid.

- Boots off the Ground means personnel spend less time going in and out of the facility, onto the drive approach. In a drive-thru application, employees stay safely inside the building and focus their time on the loading and unloading process.

- Constant-Contact Controls allow the operator to extend lip or stop platform and lip at any time during leveler travel – keeping the operator safely at the control panel at all times.

- Biodegradable Fluid is environmentally friendly and outperforms traditional industrial-grade fluid.

- Certified to exceed ANSI MH30.1 performance testing standards.

Forklift operators cross from facility floor to trailer bed more than 100,000 times each year. To ensure your workers are protected from chronic injuries, developed by Whole Body Vibration (AKA Dock Shock) through jarring bumps and gaps, it is important to have a proper Smooth Transition Dok System® in place.

- Two-Point Crown Control reinforces the front hinge (between the leveler deck and lip) in two places to help remove the "speed bump" felt with traditional leveler that have increased crown reinforcement.

- Constant Radius Rear Hinge gives a consistent 1/3" space between the warehouse floor and leveler deck; significantly reducing the gap that causes the jarring pain felt when crossing.

- Extended Lip Chamfer comes standard with an extended length of 3" (compared with traditional leveler's 1/3") that provides a more gradual transition from lip to trailer bed floor; helping to diminish bodily impact.

- Beam Construction includes two extra L-beams under the leveler deck which provide increased strength and superior flexibility, allowing the leveler to flex up to 4" under its own weight.

Rite-Hite warranties are backed by an exclusive network of representatives and industry leading planned maintenance programs, helping to ensure that products perform to their full potential.

- Up to 20-Year Money Back Warranty Based on the Dock Leveler Investment Guide.

- 5-Year Parts and 1-Year Labor.

- 12-Month Limited Money-Back Guarantee of Customer Satisfaction.

Gallery

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.