Supply Chain Security at the Loading Dock

Rite-Hite's supply chain security solutions, combining loading dock products with a digital platform, are vital for securing goods, reducing theft risks, and maintaining integrity in transit. These systems are key to protecting the supply chain in areas like warehousing, where cargo safety is crucial.

With the spread of global industry paired with the rise of eCommerce, top-performing companies are continuing to proactively identify the weakest links in their supply chain in order to maintain and protect their people, products and bottom line.

Over 15.5 million trucks are used to deliver goods throughout the U.S., with nearly every trip starting and ending at a loading dock. This gateway of shipping and receiving comes with a multitude of concerns, ranging from environmental control to cargo spoilage, damage and theft and even the company’s reputation. Each of these potential risks creates exposure to a loading dock’s supply chain security.

Debris & Outside Elements

The first step to helping protect cargo and a company’s bottom line is starting where the supply chain starts – the loading dock. One of the main contributors to product spoilage is improper environmental control. The seal around your door helps prevent contamination from outside factors – temperature differences, dirt, debris, and pests. The easiest way to tell (and how OSHA examines cleanliness) is checking for unwanted airflow and white light. If this is getting through your loading dock door, so is everything else.

The federal government has put in place guidelines and programs, especially in the food and beverage industries, that are designed to protect the public from both intentional and unintentional harm as products make their way to consumers. Its critical to pay close attention to initiatives launched by the federal government, the impact these have on the supply chain, and how to avoid waste due to unsuitable cargo.

Federal Agencies:

Department of Homeland Security

Food and Drug Administration (FDA)

U.S. Department of Agriculture's Food Safety and Inspection Service (FSIS)

Federal Motor Carrier Safety Administration (FMCSA)

US Customs and Border Protection

Cargo Spoilage & Damage

When it comes to food, the USDA estimates that 30-40% of the world’s food supply is wasted in the US, with spoilage happening at every stage of production and supply chain. Goods, either spoiled or damaged in transport, can cause significant expenses that affect a company’s bottom line. Returned shipments during a single holiday season can total around $32 billion, with an estimated 20-30% related to cargo damage.

Cargo Theft

Along with being aware of cargo spoilage and damage, facilities also need to combat cargo theft. The issue of cargo theft has emerged as a critical and growing challenge, with over $44 million lost every year. It can happen at any point where the trailer is left alone, even at seemingly secure locations like warehouses, commercial yards, distribution centers and loading docks.

Substantial losses are incurred by all companies along the supply chain journey due to cargo damage, spoilage, and theft, which not only impacts their financial standing but can also severely damage credibility and reputation. Fortunately, Rite-Hite® offers an extensive range of products designed to effectively address and mitigate these challenges.

The Rite Solutions.

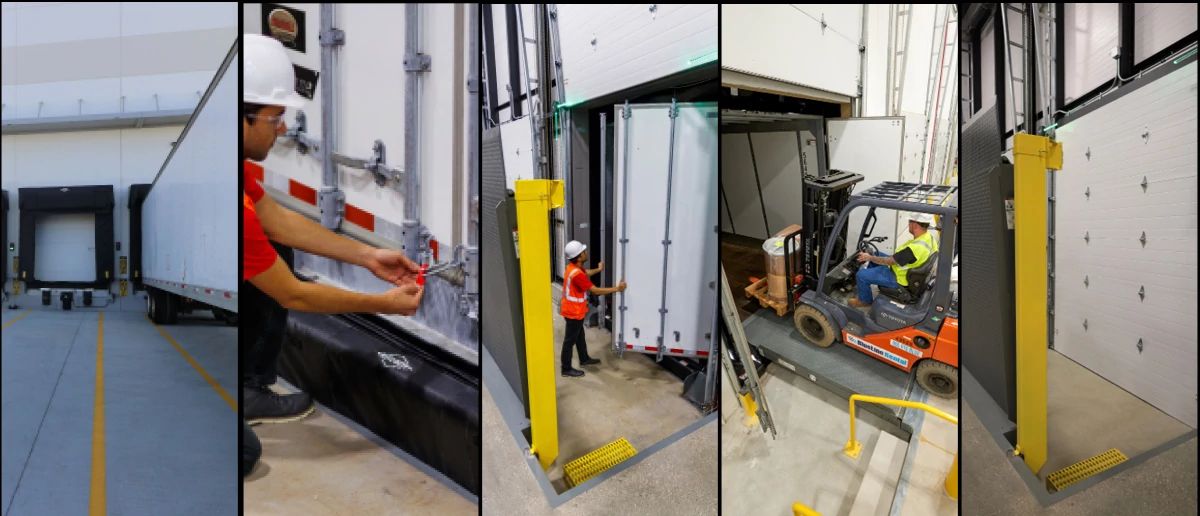

The Rite Solution in most instances is a systematic approach that incorporates a full loading dock system, with each piece of equipment working in a safe sequence of operation to help protect the most vulnerable point in the supply chain.

- Vertical storing dock levelers help minimize the bumps felt crossing from warehouse floor to trailer bed by up to 50% with its expertly engineered Smooth Transition Dok System®. This not only keeps cargo from shifting, minimizing costly cargo damage, but also addresses employee injury due to dock shock. Vertically stored levelers further enhance supply chain security when part of a drive-thru application.

- Drive-thru application helps create a sequence of operation that ensures the loading dock door is only open when a trailer is present; mitigating unnecessary exposure to outside elements as well as creating 360 degrees of protection at the loading dock.

- Trailer backs completely to the dock position with trailer doors shut.

- Vehicle restraint is engaged and can be verified on the Lok-Vu™ monitor.

- Dock seal & shelter forms a complete 4-sided perimeter seal around trailer door.

- Overhead door is opened.

- Security seal is checked and cut inside the facility.

- Trailer doors are unlocked and opened.

- Vertical storing leveler is placed in trailer bed.

- Once loading / unloading is complete, trailer doors are shut, locked, and security seal is placed.

- Overhead door closes to dock leveler pit floor.

- Vehicle restraint is disengaged.

- Trailer departs for next step of the supply chain journey.

Applications where drive-thru is not possible can adopt a Closed Door Policy. Both options help limit cargo access to facility personnel inside the building, greatly diminishing the risk of product contamination and theft. Closed door policies also protect personnel from vacant drop off at the loading dock. For additional environmental control, weather seals can be added to the leveler sides at anytime.

- Vehicle Restraints help secure the truck to the building, helping to prevent cargo theft and reduces contamination. Stabilizing vehicle restraints are recommended for enhanced smooth transition at the loading dock, as it helps prevent horizontal and vertical movement of the trailer during loading and unloading.

Rite Here for You.

As consumer demand continues to grow, its imperative to understand security risks and proactively plan for the protection of goods from damage and theft, and prepare your facility to combat outside elements. This starts with the most susceptible location of the supply chain - the loading dock. Whether implementing a Closed Door Policy or designing for Drive-Thru Application, choosing the right loading dock design, equipment and controls is critical to ensuring a safety policy’s success. Rite-Hite has a vast network of loading dock experts ready to help create a solution that meets your facility’s needs. Speak with your local representative today to ensure supply chain security at the loading dock!