Full-Time Loading Dock Communication

OSHA cites that the 2nd most frequently reported safety violation is a facility failing to communicate potential hazards. And hazards around the loading dock are everywhere – inside and outside, on and off fork trucks as well as moving or stationary. To help prevent these hazards from becoming near-misses and accidents around the dock, full-time communication of all loading activities is needed. The first critical step is to provide clear, active vehicle restraint status by way of a full-time light communication system.

By actively communicating restraint status inside and outside the loading dock, facilities help reduce the amount of trailer separation accidents. Outside, this helps reduce the risk of truck drivers prematurely pulling away from the dock position. While inside the facility, light communication systems mitigate the risk of dock workers and forklifts entering or exiting from an unsecure trailer. Without active restraint status, material handlers are also at risk of running off the edge of dock when entering or falling between the dock and a departing trailer when exiting.

The Rite Solution.

Standard with all Rite-Hite vehicle restraints, light communication systems provide active loading status to material handlers inside and truck drivers outside. The system utilizes universally recognized red (stop) and green (go) lights and is comprised of an interior control box and exterior traffic-style light box. The components work in tandem, with the interior and exterior lights changing simultaneously upon restraint engagement or disengagement. For example, when a dock worker presses “Lok” on the Dok-Lok® controls, the interior lights on the controls change from red to green while the traffic-style lights outside change from green to red.

Full-time light communication systems are offered as standalone solutions for loading docks with Dok-Lok vehicle restraints or facilities that use competitive equipment or choose to simply chock tires, helping enhance safety at every dock. Facilities that purchase a Dok-Lok or choose to incorporate standalone light communication systems versus a simple traffic-style toggle light box can further enhance loading dock safety and efficiency by:

- Interlocking compatible loading dock equipment into a safe sequence of operations

- Incorporating additional equipment as budget and time allows

- Proactively communicating unsafe restraint situations, such as missing or broken RIGs

- Capturing smart data and analytics, such as fault modes and cycle counts

Taking Loading Dock Light Communication to New Hites.

Rite-Hite took loading dock accident prevention one step further in 2009 when they introduced Rite-Vu™ Hazard Recognition and Control. Recognizing that interior light communication on control boxes is oftentimes compromised by stacked pallets or facility layouts, amongst other factors, it became evident that communication of restraint status needed to be extended. Corner-Vu™ and Leveler-Vu™ provide immediate line-of-sight loading status to material handlers entering and exiting trailers, mitigating control box obstructions while increasing safety and productivity. The enhanced system helps facility managers understand loading dock operations with at-a-glance confirmation of dock positions either being actively loaded or waiting for the next trailer to arrive. The ancillary components include:

In 2017, Rite-Vu was enhanced to include additional audible and visual alarms inside and outside the dock to address concerning trending statistics. Inside facilities, there are over 80,000 reported forklift accidents involving a pedestrian annually. Outside of facilities, OSHA cites semi-tractor trailers as the 2nd leading cause of back over fatalities in the United States. Rite-Vu’s portfolio of safety solutions address these potential blind spots by extending lifesaving reaction time to help reduce near misses, accidents, and potentially fatal injuries include:

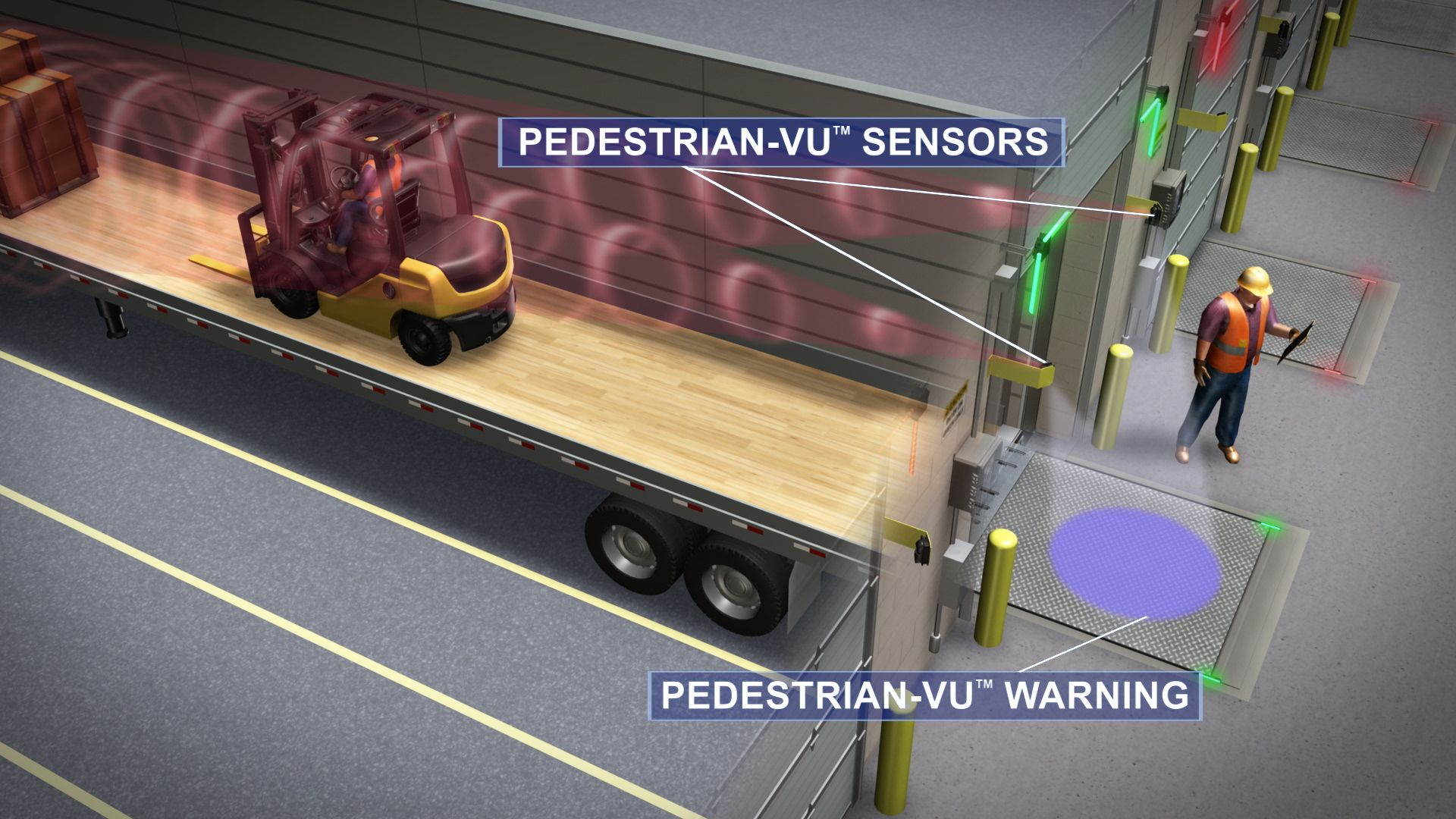

- Pedestrian-Vu™ pre-collision warning system continuously monitors inside the loading dock for pedestrian and material handling activity. When activity is sensed, a flashing blue light emits onto the leveler extending reaction time by 10x communicating to those nearby to proceed with caution. The system can be interlocked with any Dok-Lok® vehicle restraint for additional safety features, such as: preventing disengagement when activity sensed inside trailer and prompting an alarm if unsecured trailer is entered.

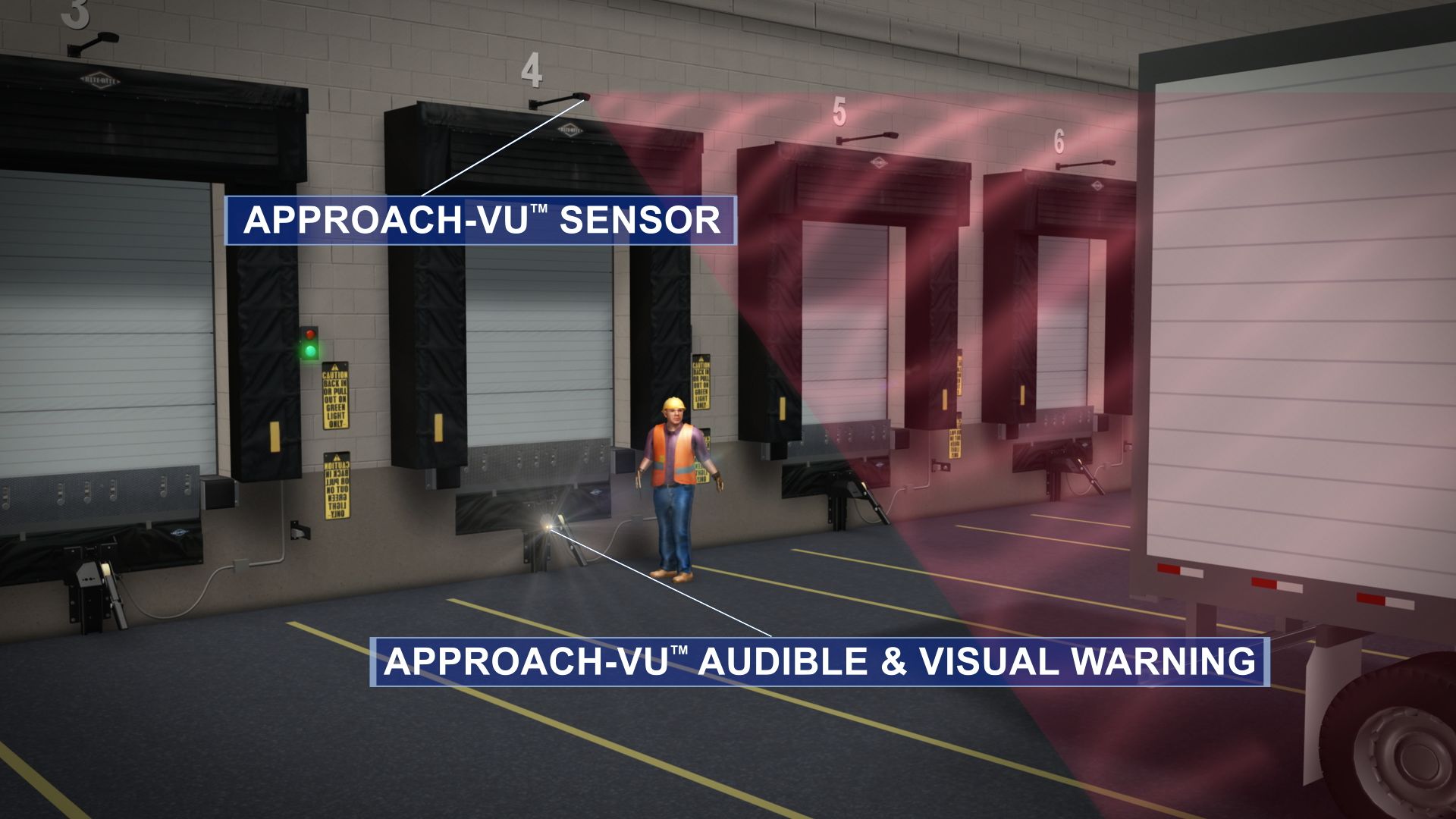

- Approach-Vu™ proactive drive approach system provides visual and audible warning when activated by the presence of a backing vehicle in the drive approach. This advanced notification indicates the need to safely vacate the drive approach due to a looming threat. It can be mounted directly to the outside dock wall or embedded in a Dok-Lok® vehicle restraint.

- Lok-Vu™ trailer presence and lock verification system helps keep boots off the ground and maintain supply chain integrity. The system helps to confirm when a trailer is present and properly secured as well as verify trailer stand presence, eliminating the need for workers to step outside on the dangerous drive approach. It is available as a single or dual camera option, displaying exterior camera view on an interior Dok-Commander® panel or as standalone monitor.

Rite Here for You.

Ensuring loading dock safety is crucial due to the high frequency of reported safety violations related to the failure to communicate potential hazards, as identified by OSHA. The implementation of comprehensive safety measures, including full-time light communication systems and innovative audio visual motion-sensing technologies, is essential to help prevent accidents, reduce the risk of trailer separation, and enhance overall workplace safety. Learn more about full-time light communication systems from a loading dock expert today!