- Home

- News

- Dock Levelers vs Edge of Docks

The Difference Between Loading Dock Levelers and Edge of Docks

To bridge the gap between warehouse loading dock and truck trailers, businesses will commonly use either dock levelers or edge of docks. The objective of these products is the same: create a safe and smooth transition between the trailer bed and dock.

A smooth transition at the loading dock is important to ensure cargo and workers are safe from tripping up on uneven surfaces. Pedestrians, forklifts and other material handling equipment are all at risk, especially during loading and unloading operations. Although the main objective of each product is the same, there are several key differences between loading dock levelers and edge of docks which should be considered before deciding what will work best for your needs.

The first thing to note about traditional dock levelers is that these are mounted within a loading dock pit. When a truck comes to the dock, the leveler is then raised up and a lip folds out, connecting the dock with the trailer bed.

Compared to edge of dock levelers, the design of traditional loading dock levelers creates a safe bridge for a wider variety of dock and trailer sizes. It’s this flexibility that really sets the two apart from one another. The size of loading docks and the heights of truck trailers are standardized to a degree, but dock heights do tend to vary, which is why dock levelers may be needed for your loading dock operations.

Loading dock levelers also offer a greater number of options for incorporating loading dock communication and safety controls than edge of docks. This allows for multiple pieces of dock equipment to be interlocked, which enables a customizable sequence of operation to ensure safety and security for trailers and personnel at the loading dock.

Last but not least, traditional dock levelers offer a wider variety of leveler styles to fit your loading dock needs and restrictions, including:

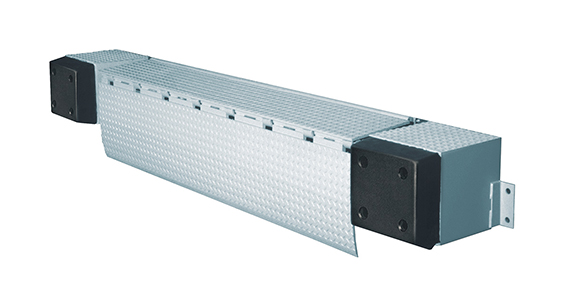

As opposed to traditional dock levelers that are mounted within a dock pit, edge of docks are designed to be mounted directly to the dock face. While this configuration offers less flexibility for handling a variety of dock and trailer heights, edge of dock levelers are perfect for warehouses or industrial facilities that service trucks with minimal height differences. Captive fleets, for instance, will typically have a predictable, standard height.

Edge of dock levelers have similar functionality to traditional dock levelers—the lip is raised up, extended and then lowered to bridge the dock to the trailer bed.

If your facility has limited working ranges, light load capacities and tight centerlines in the drive approach, it may make more sense to utilize edge of docks. In addition, the ease of installation and generally smaller investment, since constructing dock pits can be costly, can make edge of docks more attractive to businesses with tighter budgets.

At the end of the day, traditional dock levelers and edge of docks have the same purpose, but their differences make them ideal for very different types of loading dock setups. Before you make your decision, we recommend talking to an expert that can listen to your needs and loading dock restrictions so you can make the most informed decision possible. Click here to talk to a Rite-Hite representative today.

Additional Resources on Loading Dock Levelers and Edge of Docks:

Contact Us to Learn More